PLC Programming Basic

If you’re interested in learning about PLC, however, you aren’t confident where to begin, then our Beginner’s PLC Overview blog collection is perfect for you! When you have read this, you need to have the ability to identify the essential elements of a PLC system and possess a fundamental comprehension of the function and purpose of PLC (and PAC). When you finish this collection, you need to be prepared to start learning PLC programming if you opt to continue this.

HISTORY

Industrial automation started long before PLCs. From the first to mid-1900s, automation has been usually done using complex electromechanical relay circuits. On the other hand, the number of relays, wires, and distance required to make even easy automation was debatable. Countless relays could be essential to automate an easy factory procedure!

View Our Advance Training Course on PLC

NOTE: On a fundamental level, electromechanical relays operate by magnetically opening or shutting their electric contacts once the coil of the relay remains energized. They’re advantageous apparatus and play a vital role in industrial automation to get a more comprehensive lesson about electromechanical relays to check out this article.

In 1968 the first programmable logic control came together to replace complex relay circuitry in industrial plants. The PLC was developed to be easily programmable by plant engineers and engineers who were already knowledgeable about relay control and logic schematics. Since the start, PLCs happen to be wired using ladder logic that was developed to mimic control circuit schematics.

To get our products to visit our product site

Ladder Logic Example

As you may see, ladder logic appears like easy control circuit schematics where input resources such as switches, push-buttons, proximity detectors, etc. are displayed on the left and right output signal sources are posted on the right. The capability to program complex automated procedures with an intuitive interface such as ladder logic made the transition out of relay logic to PLCs much more comfortable for most in the business.

Although the very first PLCs were quite constrained in their memory and rate capacities, they immediately improved through recent years.

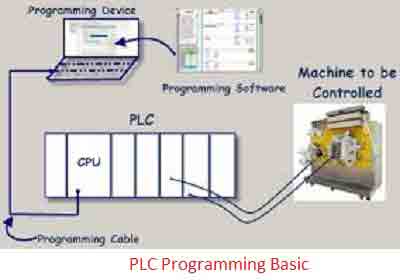

PLCs could be described as little industrial computers using modular elements designed to automate management procedures. PLCs are the controls behind virtually all contemporary industrial automation.

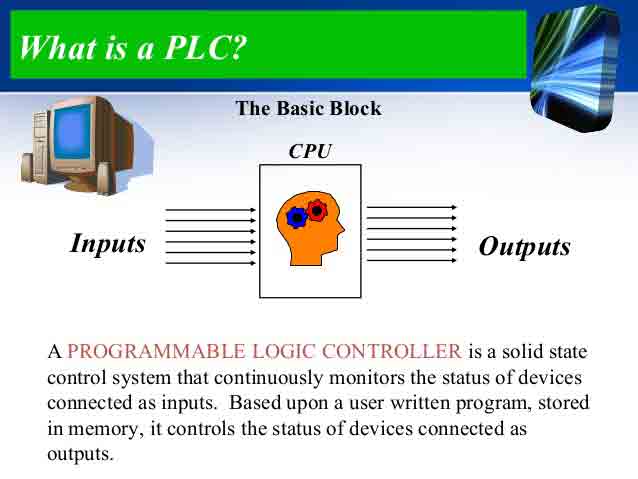

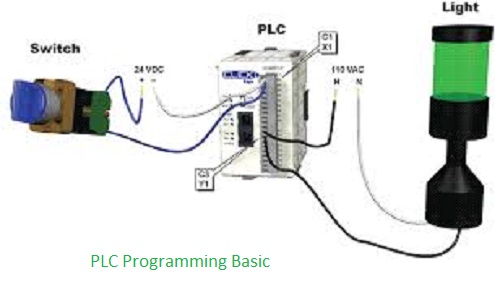

PLCs are complicated and powerful computers. However, we could explain the role of a PLC in straightforward terms. The PLC requires inputs, plays logic about the contributions from the CPU and turns off or on sparks based on that logic. In this process:

- The CPU tracks the status of these inputs like switch on, proximity detector away valve 40% available, etc.

- The CPU carries the data that it gets out of the inputs, performs logic about the information,

- The CPU works the sparks logic exp. switch off the engine, open enclosure, etc.

The dishwasher includes inputs, outputs and, clearly, a CPU. A few of the contributions to the dishwasher control are the buttons on the front, the water detectors, and the door change. A number of the dishwasher presses are the water valves, so the warmth elements as well as the pumps. Now let us consider the way in which the dishwasher employs those different elements.

Today you if you’ve got a better comprehension of precisely what PLCs are, their background, and the way they work. So make sure you listen to that!

View our All course

Propecia Trigliceridos Caracteristiques Clomid Vendita Cialis In Contrassegno viagra Combivir Cialis 5 Mg Price Walmart