PLC Automation

The PLC Auto Control System is an industrial electronic computer program that has already been ruggedized and accommodated for the management of manufacturing processes, such as assembly lines, or autonomous apparatus, or some other action which needs high-reliability power and simplicity of programming and process fault diagnosis.

This system was developed in the car manufacturing sector to offer flexible, ruggedized and readily programmable controls to substitute hard-wired relays, timers and sequencers ever since that time they’ve been broadly embraced as high-reliability automation controls acceptable for harsh environments. A PLC is a good illustration of a difficult real-time system because output results have to be generated in response to input requirements within a restricted time. Otherwise, the accidental operation will end up. We will describe more about this topic. Let’s move on

Visit Our Siemens PLC Product

Why is PLC utilized in automation?

PLCs are used in several machines, in several sectors. We know it stands for Programmable Logic Control (PLC). Structured Text is similar to conventional command-based pc programming; utilized in the former example.

Applying field of PLC Automation

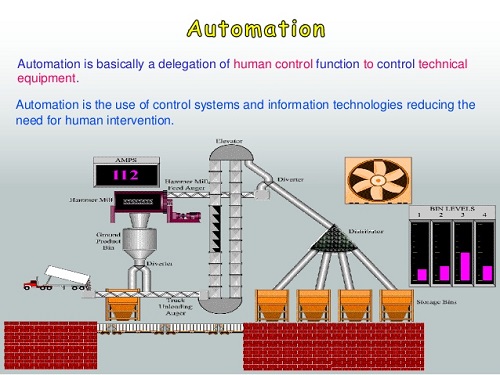

Industrial automation is using robots and computers to employed it correctly; automation may raise the quality, security, and precision of those procedures. It is the task of the men and women in industrial automation to design the programs, configure the controls, and track the operations. This class offers a summary of the subject, designed to assist anyone hoping to go into the area in a function such as mechanical or electrical engineer, automation tech, or layout supervisor.

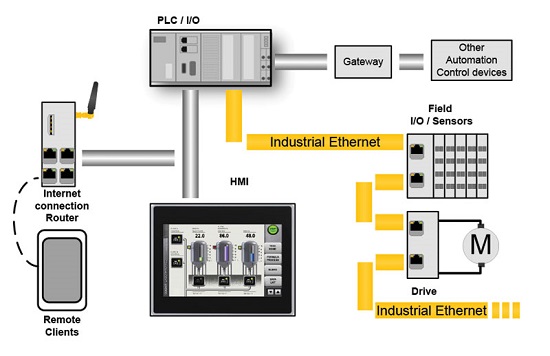

Learn about the elements and networks included at every degree of automation: discipline level, control amount, and management degree. Learn more about different apparatus included, in the programmable logic controls (PLCs) on the factory floor to OPC applications that provide technicians with insights into surgeries.

View Our Advance Training Course on PLC

The performance of this PLC has evolved Through the Years to Control systems, and media. The information management, storage, processing capacity, and communication capacities of some contemporary PLCs are roughly equal to desktop computers. PLC-like programming Together with remote I/O hardware, let a general-purpose desktop to emphasize a few PLCs in particular applications. Heavy industry since the desktop computers operate on less secure functioning Systems than do PLCs, and since the desktop hardware is typically Not designed to precisely the very same levels of tolerance to humidity, temperature, Vibration, and endurance as the chips used in PLCs. Operating systems such as Windows don’t give themselves to deterministic logic implementation, together with the Result that the control might not always react to fluctuations in input status with the consequences in time

anticipated from PLCs. The desktop logic software finds usage in less critical situations, for example, lab automation and utilize in Small centers in which the program is less dangerous and demanding because they usually are not as costly compared to PLC.

View our All courses

An intriguing discussion is definitely worth comment.

There’s no doubt that that you ought to publish

more on this subject, it might not be a taboo subject but typically people do not speak about such

subjects. To the next! Cheers!!

Achat Lioresal 25mg Valacyclovir where to buy cialis online safely Principio Attivo Paroxetina