Best PLC Training Course

Introduction to Programmable Logic Controller

PLC, firstly invented by the American company named Bedford Association. At first, it was included with much heavy equipment and later it was renovated by the technician and become one simple usable machine. It was invented to mobilize the industrial work, later it not only increases industrial work but also it reduces human efforts, to get maximum efficiency from the machine and control them with human logic, to reduce complex circuitry of the entire system, to eliminate the high cost associated with the inflexible relay control system. In a PLC, there are some basic components without which PLC is nothing.

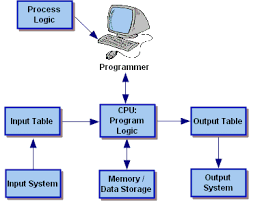

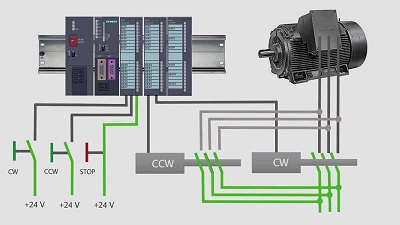

PLC has an Input module, Power supply, Microprocessor, A programming device, and an output module. A Programming device in a PLC works as logic without which PLC is just like a hardware empty box. Basically, logic in PLC controls all types of programming. Another device is Microcontroller which is considered as the heart of a PLC. The power supply of PLC is basically 24v to the 48v. The input modules usually get signals from the sensors via the push button, switch button, toggle button, limit button, and so on.

This gives the input to the microprocessor, and it processes according to the program and the output is given in the output module. The input modules basically accept and control signal from the sensors into a logic signal and then the output module converts the control instructions into a signal that can be used by the actuators. The CPU in a PLC consists of the Arithmetic logic unit, internal memory of CPU, and internal timers, counters, and flags. The major and most important component of a PLC is the memory. There are two types of memory- RAM and ROM which is erasable any time when a new program is needed to update. It requires the power supply which provides the voltage needed to run the Primary PLC components.

View Our Advance Training Course on PLC

There are three types of Programming in a PLC. Ladder logic, Sequential programming, and flow-chart programming. Among them, the Ladder logic is very easy to operate as a simple technician in an industry can operate it properly, another one is the sequential programming which works in a sequence, which means every program writes in a numerical sequential method. The ladder logic is the oldest programming language where there are two rails. The left one is positive and the right one is negative.

Basic thing one must know before the Best PLC training course

Before getting the best PLC course in a training center, one must know the basics of electronics and the basis of logic, might be any programming language; it would be enough for one to get started with PLCs. But, in order to work in the field, one has to have knowledge of the field of application. PLCs are just a small part of the job that needs knowledge of PLCs. There are other things such as electrical wiring, power system, that might be some knowledge of hydraulic and pneumatics might help to understand the systems that one wants to control using PLCs. All the basics that one must learn for PLC start with the knowledge of Electrical Circuits and Components, Open and Closed Control Systems, and Boolean Algebra. The basic that one must know is

- Electrical Circuits and Components as the best PLC training course: The knowledge of electrical circuits and components allows one to know the basics of how the PLC works, and how to actually connect the components for the PLC. Furthermore, devices that are controlled by the PLC are electrical, hence it becomes more important to learn the basic concepts of electrical circuits.

- Control Systems learning as the best PLC training course: Control Systems are the actual application of the PLC. These consist of the larger picture of the PLC application- this is where the different input conditions come into play, as well as the output wanted. What separates PLC control systems to other types of control systems is its simplicity. That said, it must not be mistaken that PLC control systems are designed easily. There must be a higher level of proactive thinking before one implement control systems using the PLC.

- Boolean Algebra and Logic Fundamentals learning as the best PLC training course: Boolean Algebra is one of the fundamentals of Digital logic. These mathematical aspects of logic are simply termed as the simplifier of a whole process and it helps to know this in order to become more cost-efficient in designing a system. One, of course, has to know how logic works. Without it, one would not be able to design systems based on Several input conditions for the fact that the PLC programming requires careful design. Fortunately, simulation is available to a design mistake that could easily be identified early on where it is still easy to fix.

- The process of Manufacturing learning as the best PLC training course: Lastly, one should also be aware of the process of manufacturing, the input-output, other parameters, the type of PLC that the client wants to use in his factory.

Best PLC training course in the Bangladesh Automation Technologies

In Bangladesh, specifically in Dhaka, one training center that really working very well and has given varieties of PLC training with a practical learning benefit. By having training on the best PLC training course from this training center, one will able to know:

- PLC Architecture learning as the best PLC training course: The basic architecture of a PLC consists of main components- the processor module, the power supply, and the I/O module.

- CPU module of PLC: CPU module is the soul of a PLC. Without the CPU, PLC is just like hardware which has no role to function. This module typically stays in the slot beside the power supply. The CPU consists of a microprocessor, memory chip, and other integrated circuits to control logic, monitoring, and communication.

PLC-BUS or Rack: In the PLC, Buses are the paths through which the digital signal flows internally of the PLC. There are four types of Bus. The control bus transfer signal related to the actions that are controlled internally. The address bus sends the location’s address to access the data, And the system bus facilitates the I/O port and I / O unit to communicate with each other.

To get our products to visit our product site

- ABB PLC Power Supply: ABB automation devices deliver solutions with high performance and flexibility to be effectively deployed within diverse industries and applications including water, building infrastructure, data centers, renewable energy, machinery automation, material handling, marine and more.

- PLC I/O Modules: There are various I/O module in the PLC which work through the programming language. Such as Chassis-based I/O, embedded distributer I/O, Distributer I/O in cabinet box, Distributed I/O in cabinet modular, Distributer I/O on machine box and so on.

- Integrated or compact PLC: PLC is integrated as either single or modular units. An integrated or Compact PLC is a mini-sized PLC that is designed as a compact and robust unit mounted or placed beside the equipment to be controlled.

By getting the Best PLC training course in the Bangladesh Automation Technologies one also can learn 5 types of PLCs- AB, Siemens, Omron, Delta, and Schneider. The training centers are providing the best course on PLC, designed to make one comfortable while working on different PLCs.

This Best PLC training course equips the beginner with no prior PLC programming working experience with the basic application necessary to develop a complete PLC program. Through this, one will able to develop PLC programs from scratch. One will be having a firm knowledge about ladder logic, PLC programming, and an in-depth understanding of a standard HMI. Participants will learn the difference between analog and digital signal and how to bring them into a PLC, process them, and send them back out. Participants will be acquainted enough with ladder logic instructions to develop a PLC program from scratch. Students will explore standard controls techniques for things such as level control, HOA control, pump control, and PID control loops.

One can know the working principle of relays and how they communicate with contacts. Also, one can understand the difference between PIC Microcontroller and PLC. One can learn various methods for programming PLC. One course becomes best when it gives its user all the technical and practical knowledge, he needs to be the best in his future career. In the education system of Bangladesh, where theoretical knowledge is given the highest priority than practical learning. Even the lab classes are also taken on a very minor project.

That’s why engineers after completing graduation cannot find any appropriate job due to lacking experience and practical knowledge. In this case, Bangladesh Automation technology has given chance to the novice student to brush-up their engineering knowledge with the golden touch of practical experience. The syllabus-based method only can give one the highest GPA but not a good career path. Every year it is seen that many brilliant result-makers are fighting to have a good job. Their level of experience is below the technician in an automation factory. In the Bangladesh automation Technologies, the trainers are very friendly and easy-going, and the class size is not very congested, and the equipment that is there to teach one thing about the machine, one can have the chance to operate it by his own and learn things slowly. The course program duration also a standard duration that makes a student efficient enough to learn practical things at a good pace.

Importance of Best PLC training course:

Automation s everywhere and has taken a pivotal role in today’s industrial age making many companies dependent on PLCs and PLC-trained personnel. So, one is new to PLCs, never heard of them, or know them well, it may be time to get training and be proficient in it. There are many reasons why the best PLC training course is needed. They are:

To get our products visit our product site For Siemens PLC Product

Career opportunities:

For those who may not know about automation or PLCs, allow me to explain. Automation is defined by Google as the use of largely automatic equipment in a system of manufacturing or another production process. That is true, but for a more awesome explanation let’s talk about the manufacturing system of frozen pancake. In a factory, 45000 pancakes are made per hour. Which is simply impossible for a manual service? As you can see, automating this process has clear advantages. However, behind all these manufacturing methods which work is the brains behind the operation or what controls the timing, temperature, level, speed, etc. of these processes. That is, of course, a controller like the PLC or Programmable Logic Controller. Getting the training one needs to develop, installs and supports PLC systems like these can open up a wealth of career opportunities for you. Who wouldn’t want that?

Minimizing the learning curve:

Now, for those of you who work with PLCs but are just starting out, PLC training is a great way to get ahead of the curve. I was very fortunate when I started my Control Engineering Career. A local company took me in and showed me everything there was to know about PLCs and PLC programming. But if you don’t have someone available to train you, there are many places that offer PLC training. And with PLCs, a little training can go a long way. Even the slightest hands-on experience can further your understanding and get you ready for the career ahead.

Staying ahead of the Game:

For staying ahead in the game PLC learning is a benefit. “I work with PLCs every day, I don’t need training.” Like any technology, PLCs are constantly advancing and keeping up with new developments can benefit you as well as your company. These days the minute you buy the newest technology it is on its way to being obsolete. PLCs are no different. Advances in hardware and software are making PLCs more efficient, user-friendly and cheaper. For instance, a lot of controllers can now interface with mobile apps for remote monitoring, something that wasn’t available when I was trained. It is always a good idea to stay informed of what may be coming next.

For keeping options open:

Firstly, a lot of companies are turning to automation to stay profitable. An understanding of what automation is and how it works could afford one the knowledge of how to automate some of the processes you do work with, saving you time and your company money. Besides that, it is always good to have a plan B for your career and PLC training can give you the mobility to move to another career field in case the need arises.

To get our products to visit our product site

Advantages and disadvantage of PLC:

Though PLC is undoubtedly a blessing for industrial automation, but nothing comes without any disadvantage at all. Some disadvantage of PLCs is:

There is too much work required in connecting wires.

There’s a difficulty with changes or replacements.

Its always difficult to find errors, And require the skillful workforce.

When a problem occurs, hold-up time is indefinite, usually long.

Advantages of PLC:

Rugged and designed to withstand vibrations, temperature, humidity, and noise.

Have interfacing for inputs and outputs already inside the controller.

PLCs are easily programmed and have an easily understood programming language.

PLC software benefits for industrial manufacturers:

Software-based programmable logic controllers present numerous advantages over traditional hardware products and the addition of software systems enables greater productivity, detailed reporting for optimization and overall system flexibility.

Many of these capabilities go directly against the traditional, physical production line concepts of manufacturing. Technology is bringing production into a new era. Likewise, the advantages of using software-based PLC are significant. Networking is crucial for any organization, and in any given company, there may be several different types of networking systems.

One benefit of software-based PLC is they facilitate simple integration of networking systems for easy communication. This opens the door for numerous productivity benefits and provides upper management with a simple platform where operations can be monitored.

Another major benefit of software-based PLCs is they provide safety and security advantages over hardware appliances. In traditional models, information is held within the system and is vulnerable to unauthorized access and other risks. PLC software only gives information to those who are authorized and comes with more advanced security features. Software-based PLCs can also help cut production costs.

Input-output devices connected to the PC system use Ethernet cables. These are the most cost-effective than traditional PLC connections which had large connections and many applications. Ethernet cables are faster and increase the speed of the workflow.

There are many advantages of software-based PLCs, but the networking, safety, and cost benefits are some of the biggest and most immediate ones. Software-based PLCs bring productivity to just about any operation.

So, lastly, we can say that Programmable logic controllers or PLCs are highly specialized, programmable microprocessor-based controllers used to control a specific application on a machine or a process. They are used in automation and manufacturing to control assembly lines and machinery on factory floors as well as many other types of mechanical, electrical, and electronic equipment in a plant. They can be used in applications ranging from vending machine controls and packaging machinery to the roller coaster and complex camera positioning systems. So, PLC is undoubtedly a boon to the industry.

View our All course